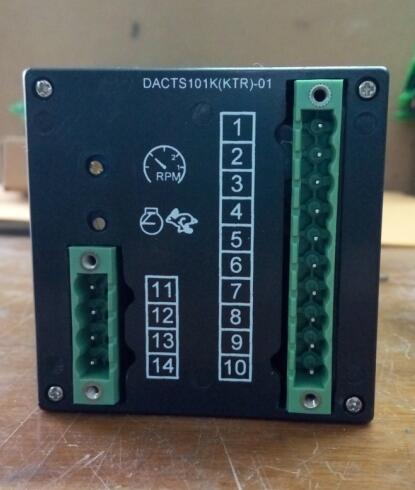

DACTS101K

Date:2017-02-22 Click:5135

DACTS101K DIESEL CONTROL MODULE

1. DESCRIPTION

The model DACTS101K is a diesel control module, it is used to manually start and stop the diesel via a key switch on the front panel, automatically shutting down the diesel when the diesel fault conditions and indicating the failure by LED.

Operation of the module is via a three position key switch mounted on the front panel, the key switch has three positions, they are stop(O), run(I) and start(II),

when the switch is in the “stop(O)” position, the DC supply is removed from the module and the run relay is de-energized. The module is powered up when the “run(I)” is selected, the run relay is then energized, the diesel fuel system is energized and the protection hold-off timer is initiated. If the switch is turned to “start(II)” position and held against the spring return, a positive supply output comes from no.4 terminal, Once the diesel has started, the switch should be released and it will return to the “run” position automatically.

When the diesel is being attempted to start, as soon as the key switch is turn to “run” position, the switch should be moved to the “start”, or else the protection hold-off timer has expired, the diesel can not be started for a low oil pressure fault.

Operation of any of the following alarms: low oil pressure, high coolant temperature, shutdown, overspeed will cause the run relay to de-energize. This will remove the fuel supply from the diesel and bring it to rest. The alarm output will be activated giving a positive DC output.

The module provides five alarm channels, each alarm channel has it’s own LED indicator and once activated no further alarm conditions will be accepted. The alarm output and relevant LED will remain active until the diesel is reset by turning the switch to the “stop” position.

Speed signal is derived from either the generator Hz output or the diesel magnetic pick-up (specified on ordering). The overspeed circuit monitors the diesel speed and will shut down the diesel immediately if a pre-set speed level is exceeded. This trip level is adjustable from 90% to 130% of full rated speed and is suitable of both 50Hz or 60Hz systems.

During diesel cranking and for a short time afterwards the protection hold-off timer is active and the relevant alarms inputs are inhibited. This enables the diesel to start and achieve normal running conditions. Once the timer has expired, the inputs are enabled providing normal protection from the module.

Charger failure warning is also provided by monitoring the WL terminal on the charge alternator. This operates on a similar principal to the warning lamp fitted in a motor vehicle, should the output fail the charge fail LED will illuminate. The module will also provide the alternator excitation current via this connection. A charger failure will not make the diesel shutdown.

2. SPECIFICATION

9 to 33 V Continuous.

![]() Cranking

Dropouts:

Cranking

Dropouts:

Able to survive voltage dips during

cranking. This is achieved without

the need for internal batteries.

![]() Alternator

Input Range:

Alternator

Input Range:

15 - 305 V AC RMS

![]() Alternator

Input Frequency:

Alternator

Input Frequency:

50 - 60 Hz at rated diesel speed.

![]() Magnetic

Input Range:

Magnetic

Input Range:

0.5 V to +/- 80 V

![]() Magnetic

Input Frequency:

Magnetic

Input Frequency:

2300Hz to 6000 Hz at rated diesel speed.

![]() Speed

meter Output:

Speed

meter Output:

0 – 5mA DC

![]() Start

Relay Output:

Start

Relay Output:

16 Amp DC at supply voltage.

![]() Run

Relay Output:

Run

Relay Output:

16 Amp DC at supply voltage.

![]() Alarm

Output:

Alarm

Output:

1 Amp DC at supply voltage.

![]() Dimensions:

Dimensions:

72 X 72 X 118.5mm (Excluding Key switch)

![]() Operating

Temperature Range:

Operating

Temperature Range:

-30 to +70°C

![]() Installation:

Installation:

Front panel mounting via suitable cut-out. Retaining clips supplied. Cable connections via locking plug and socket type connectors.